APPLICATION

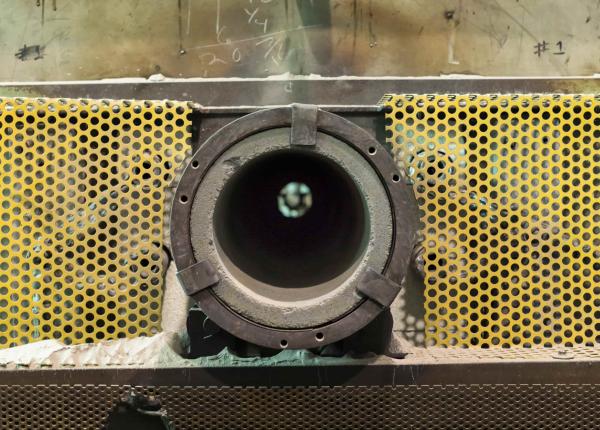

Scaling-up process: from lab scale to production; Custom furnacing raw minerals and the scale-up process.

CHALLENGE

A leading company in the melting industry had been working on making a new product using their small R&D laboratory furnace. The results of the initial R&D looked promising and they wanted to manufacture a larger batch but their furnace could only make 5 pounds of material. Their customers required at least 100 lbs in order to test the new material in their process. They had little interest in spending a lot of capital to install new capacity before they had even made enough of the material to test it in the marketplace. They needed to find a company that had the equipment and the know-how to melt and scale up from lab-scale to production quantities.