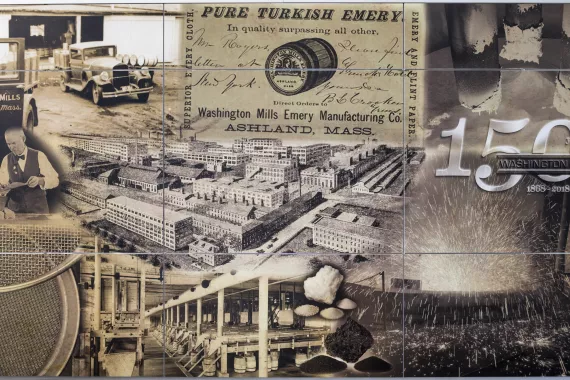

History of Fused Minerals

Established in 1868, Washington Mills was the first abrasive producer in the United States. Through its commitment to the industry and its goals of internal growth and strategic acquisitions, Washington Mills offers the broadest selection of abrasive grain and specialty electro-fused mineral products available in the market today.

Fused Mineral Properties

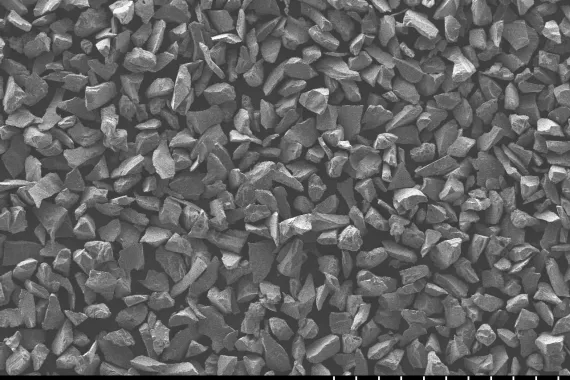

We manufacture many of our fused materials through an electric arc fusion process or Acheson furnace technology. The fusion process transforms raw materials such as bauxite, silica sand and alumina into materials such as aluminum oxide, silicon carbide, zirconia, mullite and many other fused materials. These abrasive and fused materials possess properties that make them valuable in hundreds of different applications.

Fused Mineral Industries

Fused minerals are widely used as a raw material in refractories, ceramics shapes, grinding wheels, sandpaper, blasting media, metal preparation, laminates, coatings, lapping, polishing, grinding and hundreds of other applications. The natural properties of our materials, coupled with our proprietary manufacturing processes and fusion expertise, make our materials highly effective in many different applications.

Manufacturing Fused Minerals

Washington Mills is proud to be one of the world’s largest producers of abrasives and fused mineral products, offering an exceptionally wide line of standard abrasive grain and specialty electro-fused minerals from its worldwide multi-plant locations. From the careful selection of raw materials to receiving the material on a production floor, Washington Mills makes every effort to ensure our fused minerals are manufactured with precision care.

Fused Mineral Manufacturing Experts

Our team of fusion experts are available to assist