SiC Industries

Exploring Possibilities

Dedicated to advancing our processes to cultivate new industries and uses

Dedicated to advancing our processes to cultivate new industries and uses

Washington Mills is the largest North American producer of alpha, high quality, silicon carbide macrogrits, microgrits, powders and sub-micron powders called CARBOREX®.

Silicon carbide is an abrasive used in;

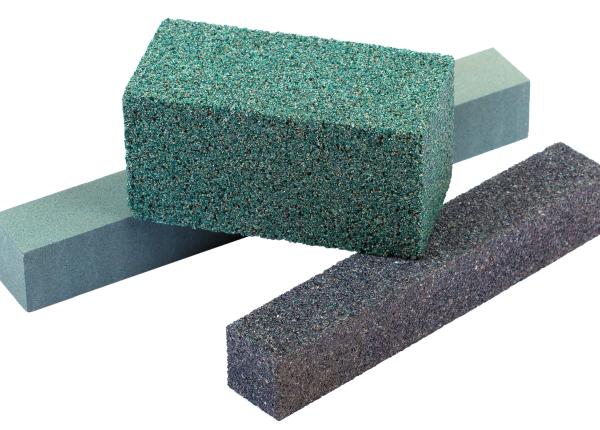

Our high quality silicon carbide abrasives are used for grinding, cutting, shaping, honing and polishing a wide variety of materials including plastics, cast iron, stone, ceramics, and non-ferrous alloys such as aluminum, copper and brass. Abrasives customers include; manufacturers of bonded (grinding wheel) and coated (sand paper), refractories, iron and steel, blasting abrasives, wire sawing abrasives, anti-slip abrasives, gem and stone polishing, and other polishing abrasives.

Washington Mills’ CARBOREX® offers high density and low porosity which is ideal for high performance applications such as advanced or technical ceramics. Silicon carbide has the ability to be sintered, recrystallized, and/or infiltrated with other materials, formed into shapes using slip casting, and extrusion or isostatic pressing. These shapes can become items such as;

Washington Mills manufactures specifically engineered powders from .3 to 20 microns with exacting chemistry, particle size distribution, and conductivity standards for you high end technical ceramic applications.

Expertly engineered CARBOREX® silicon carbide powders present a unique solution to the stress demands and thermal management challenges facing high-performance compounds.

Washington Mills’ high-performance SiC powders are designed for use as additives within the harshest electrified environments, offering reliable and efficient heat dissipation and cooling capabilities to extend the life of critical composite materials in high-stress applications.

Thermally conductive and electrically resistive CARBOREX® silicon carbide powders work within your preferred compound formula to optimize strength and thermomechanics without sacrificing flexibility of design or compromising the form and function of your base. Chemically inert, high wear resistant CARBOREX® powders offer:

A lightweight, lower-cost alternative to metals and other traditional additives, CARBOREX® SiC powder additives – integrated across a wide range of adhesive, plastic and rubber base materials – deliver top-of-class performance solutions that keep your composites meeting, and exceeding, today’s high-performance requirements and standards.

Washington Mills manufactures CARBOREX® No. 1 RF for the refractory market. The material is a high quality refractory graded silicon carbide that has an extremely high melting temperature (2,700 C) superlative for refractories. This material has a low coefficient of expansion, chemical inertness, ability to stand up to corrosive environments, and is thermal resistance which makes it an ideal material for the production of bonded refractory products. Examples of refractory applications include;

CARBOREX® No. 1 RF is offered in split sizes ranging from 4/8 to 800/F and single grit sizes from 6-1200. We can assist you with selecting the appropriate size based on your current specification or custom manufacture a size that fits just right for your process.

Washington Mills Hennepin produces silicon carbide called CARBOLON MA®. Metallurgical grade silicon carbide has low nitrogen and sulfur contents making it an ideal product for producing all types of iron. Steel manufacturers use silicon carbide as an additive to molten metal to act as a source of carbon and silicon. Silicon carbide is a prime source of silicon and carbon offering a powerful deoxidizing effect. Metallurgical silicon carbide has a silicon carbide content of less than 95% and can be effectively used in the production of steel as a solid fuel to replace hot metal or adjust temperature. CARBOLON MA imparts metallurgical benefits to the metal and enhances furnace lining life. Silicon carbide is utilized in basic oxygen furnaces (blast furnaces) to increase the overall efficiency of process by providing a fuel source for additional heat. Steel plants use silicon carbide to provide appropriate metallurgical properties to the final product.

Wiresawing is a method used to cut or slice silicon wafers, granite, marble or stone. Washington Mills’ group graded CARBOREX® grains and precision graded silicon carbide powders are used in the cutting of silicon wafers. Silicon carbide is an excellent material for wire sawing silicon metal ingots into wafers for photovoltaic and semiconductor applications. Our precise manufacturing process offers controlled particle size distribution and grain shape. High quality and precisely sized silicon carbide produced by Washington Mills reduces sawing kerf losses and improves surface quality of the wafers. In addition, this virgin material can be recycled and used repeatedly to make your process efficient.

Washington Mills offers silicon carbide samples and technical assistance when evaluating new uses for silicon carbide.