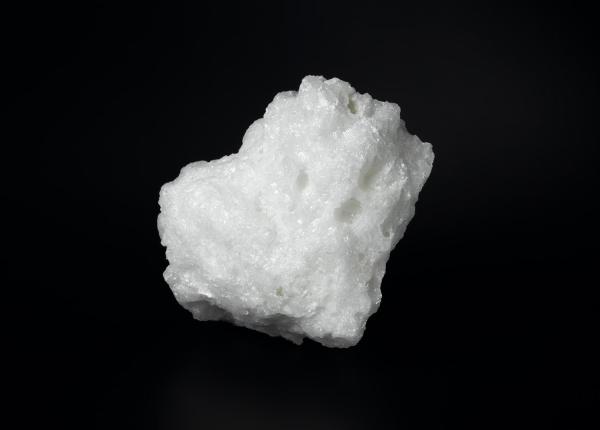

Washington Mills manufactures high-quality silicon carbide powders used in the production of kiln furniture such as; rollers, beams, plates and setters. Technical ceramics made from silicon carbide offer properties of hardness, strength, thermal conductivity, and corrosion resistance at extremely high temperatures.

Ceramics

Washington Mills is a leading manufacturer of powders used in the production of ceramic bodies including kiln furniture, water purification filters, diesel particulate filters, body armor and others. Technical silicon carbide produced at Washington Mills’ production facility in Orkanger, Norway can provide ultra-high purity, control over particle shape and tailored powder distributions.

Ceramic products are defined as inorganic, nonmetallic solids made from oxide ceramics, non-oxide ceramics, or composites; each providing unique material properties of the finished piece, that are subject to high temperatures during manufacturing. Washington Mills produced inorganic fused minerals specifically designed for use in ceramic product manufacturing such as; technical ceramics, advanced, structural, electrical, magnetic, optical, chemical, thermal, mechanical, biological, and nuclear ceramics. Most of these products are manufactured with ceramic materials that have high density and low porosity and are used in high performance applications.

Kiln Furniture

Filters

CARBOREX silicion carbide offers inert properties for use in ceramic diesel particulate filters such as; high temperature resistance and low thermal expansion.

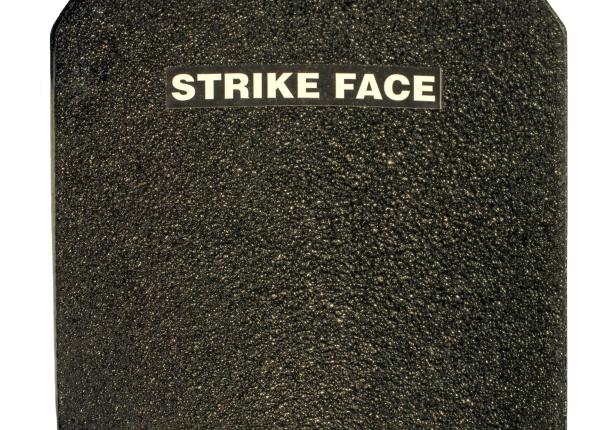

Body Armor

Washington Mills’ boron carbide is used in the production of body armor used by the United States government.