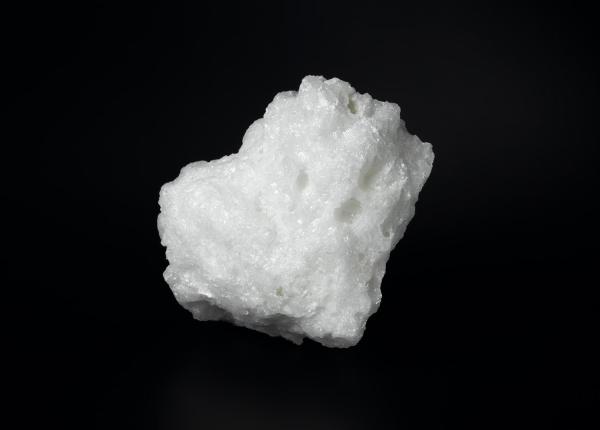

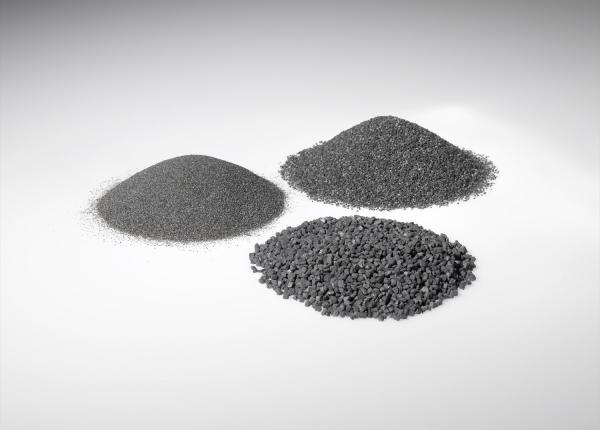

Foundries melt iron ore, iron scrap and steel scrap in a high-temperature furnace to produce molten iron. Impurities from the slag produced during the melting process must be removed from the molten iron. Silicon carbide is an important metallurgical additive, as Silicon and Carbon molecules combine with impurities in the molten metal slag, removing contaminants and increasing iron yield. Silicon carbide also releases metal oxides trapped in the slag, producing additional energy to expedite the melting process. Silicon carbide enhances the metallurgical properties of all grades of iron.

- Washington Mills is a major producer and supplier of foundry-grade materials, with multiple facilities in North America and Europe.

- Washington Mills’ foundry products are manufactured to the highest industry standards available, with both in-house testing and lab facilities.

- Washington Mills has a highly trained staff of metallurgists, technicians and production personnel available to assist you for your iron foundry needs.